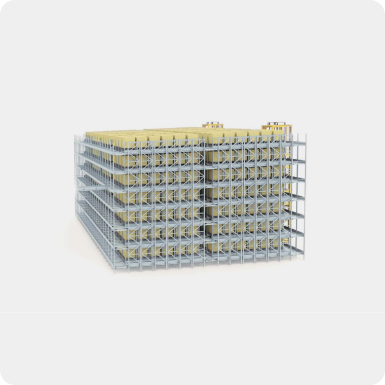

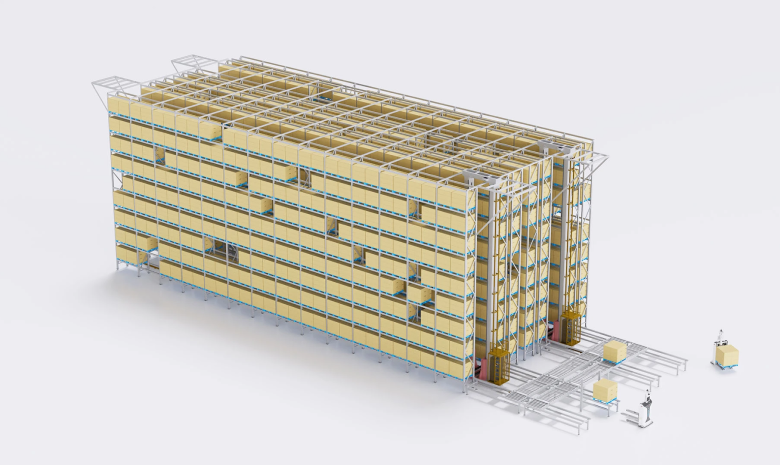

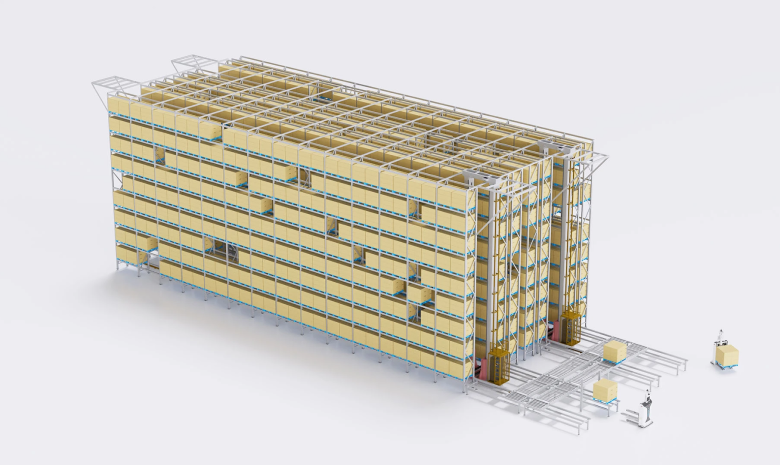

Shuttle High-Density Storage System

R-BOT 4-Way Shuttle + H-BOT Vertical 2-Way Shuttle

-

The 6-Way Shuttle High-Density Storage System, powered by R-BOT and H-BOT, is ideal for both full-pallet handling and partial-picking scenarios. Compared to conventional stacker crane-based AS/RS systems, it delivers higher storage density, improved overall efficiency, superior flexibility, and faster project lead times—making it the optimal choice for customers seeking maximum storage density and space utilization.

PDF Download

01Key Benefits of the 6-Way Shuttle System

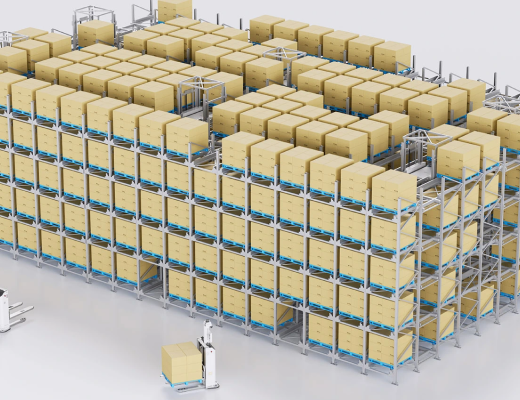

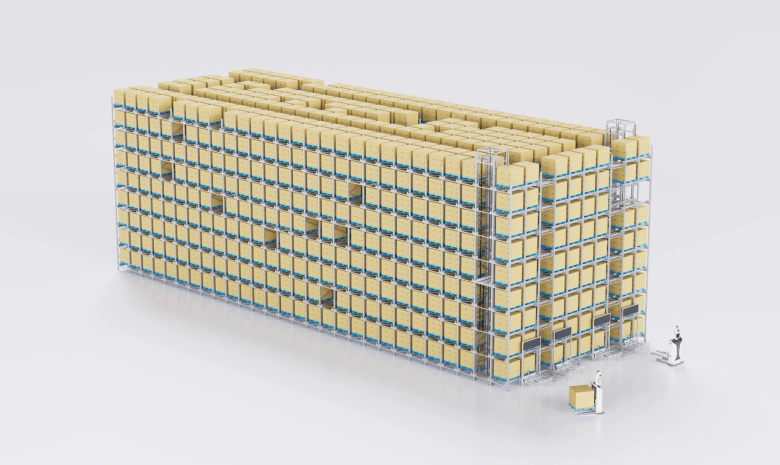

- Combining R-BOT 4-way shuttles with H-BOT vertical 2-way shuttles, this solution maximizes storage density and operational flexibility.

-

- Scalable shuttle deployment based on workload fluctuations

- Full access to all rack positions without fixed routes

- Seamless integration with conveyors and AMRs for fast in/out operations

- Superior Efficiency

-

- - 2–3× higher throughput than conventional manual warehouses

- - 15–20% more efficient compared to typical automated 3D warehouses (stacker crane AS/RS)

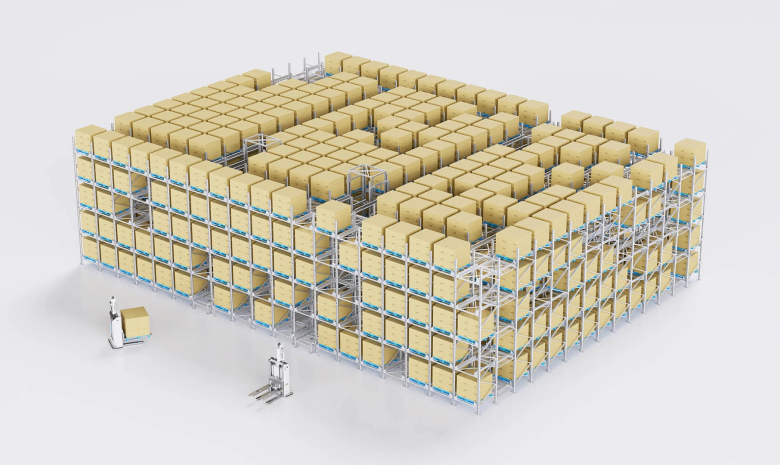

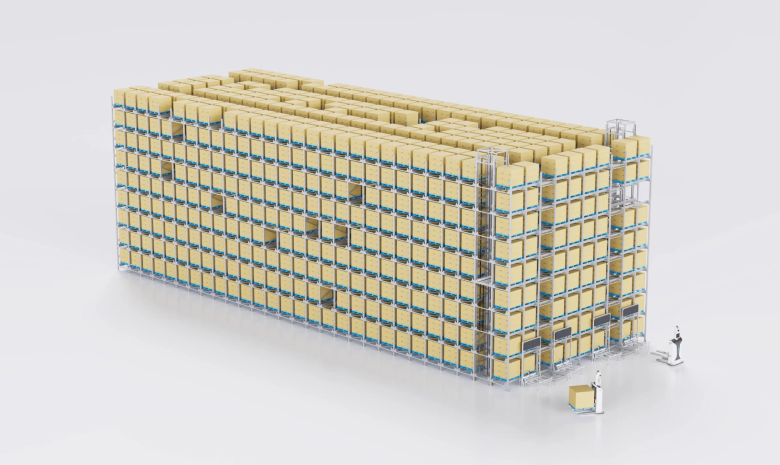

- Ultra-High-Density Storage

-

- - 4–6× higher storage capacity than conventional warehouses

- - 30–100% more storage density compared to automated 3D warehouses (stacker crane AS/RS)

- Exceptional Flexibility

-

- - Suitable for new builds or retrofits of existing warehouses

- - Ideal for complex layouts: high column density, multi-floor operations, or irregularly shaped facilities

- - Scalable shuttles can be added or reduced based on changing throughput needs

- Faster Project Delivery

-

- - Over 40% shorter lead time compared to stacker crane-based systems

- - Rapid, high-quality installation and commissioning for quicker go-live

02System Comparison

6-Way Shuttle vs. Stacker Crane AS/RS

- 01Efficiency

- Centralized cluster scheduling for all robots ensures higher, more balanced efficiency. Stacker cranes have fixed, less adaptable performance.

- 02Flexibility

- Dynamic storage planning based on SKU and cache needs; stacker cranes are rigid and lack deep space optimization.

- 03Delivery

- Standardized product with lower transport costs and shorter delivery cycle. Stacker cranes require project-specific customization, long lead times, and high energy consumption.

6-Way Shuttle vs. 4-Way Shuttle with Elevator

- 01Cost

- No elevators or conveyors needed, reducing cost per pallet position.

- 02Density

- Maximized front-area storage without reserved space for conveyors and elevators.

- 03Delivery

- Pre-tested standardized modules enable fast installation, no on-site debugging required.

6-Way Shuttle vs. Manual Shuttle Panel Warehouse

- 01Efficiency

- Automated cluster scheduling surpasses manual or semi-automated operations.

- 02Flexibility

- Supports SKU mixing and FIFO management; manual systems cannot.

- 03O&M

- Digitally managed with minimal human dependency, lowering operating costs.