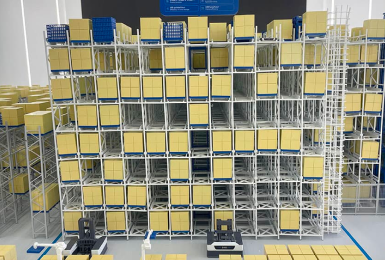

Front-Picking & Rear-Storage System

U-BOT Omni-Directional Stacker Robot + R-BOT 4-Way Shuttle

-

PDF Download

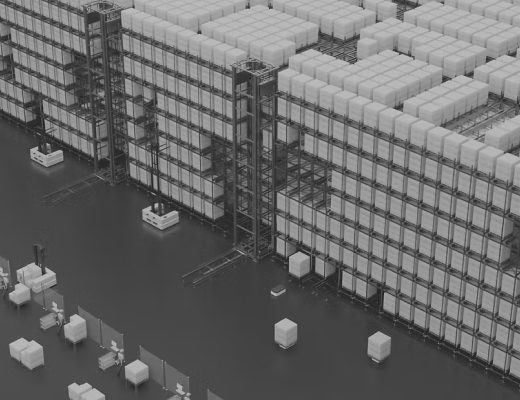

The U-BOT and R-BOT are seamlessly integrated to enable "front-end buffering and rear storage" operations. The U-BOT replaces multiple conventional handling devices such as elevators, conveyors, and AGVs, while the R-BOT efficiently manages rear storage tasks. Compared to conventional 4-way shuttle warehouses, this solution significantly improves picking accuracy and efficiency, making it the optimal choice for customers seeking maximum storage density and fast, precise picking performance.

01Advantages of the U-BOT + R-BOT Storage System

- This ultra-efficient, high-density storage and picking solution combines the U-BOT omni-directional stacker robot with the R-BOT 4-way shuttle, enabling front-end picking and rear storage operations.

- With dual control integration via PTP Smart Warehouse Software, the system achieves exceptional operational efficiency and space utilization, resulting in superior picking accuracy and throughput compared to traditional shuttle-based solutions.

- High-Density Storage

-

- - Maximizes space utilization through a “batch-wall” picking configuration

- - No fixed aisles required, allowing greater flexibility in layout

- Ultra-Efficient Operations

-

- - Fast picking without unpacking, tailored to diverse customer needs

- - Multi-depth racking structure for optimized storage and picking efficiency

- - Intelligent scheduling ensures seamless collaboration between R-BOT inside racks and U-BOT outside racks

- Rapid ROI

-

- - 2–3 years

- - Faster and simpler deployment compared to standalone 4-way shuttle warehouses

- - Eliminates need for costly conveyors and lifting devices, reducing investment costs

- Flexible Deployment

-

- - Front-end conveyor lines are not required, enabling more adaptable warehouse layouts

- - Scalable design allowing easy addition or removal of U-BOTs and R-BOTs based on order volumes

- - Supports phased implementation and expansion without operational disruptions

* The "batch-wall" approach enables multi-depth, high-density item placement without dedicated aisles, maximizing space utilization while enhancing picking efficiency.

Inbound Process

- STEP 01

- Inbound pallets are delivered to the receiving point via forklift. The PDA initiates the inbound task, and the WMS requests storage allocation.

- STEP 02

- The U-BOT receives instructions and transports pallets from the inbound point to designated storage locations.

- STEP 03

- The R-BOT moves from its staging point to the cache area at the rack front, transferring pallets to assigned positions. Pallets for higher locations are moved via elevator if needed.

- STEP 04

- Upon completion, the R-BOT reports task status, and the backend system updates inventory information in real time.

Outbound Process

- STEP 01

- Based on order information or warehouse plans, the WMS issues outbound tasks, and the WCS schedules R-BOT operations.

- STEP 02

- The R-BOT retrieves pallets from storage and moves them to the outbound staging point. High-level pallets are pre-positioned using an elevator.

- STEP 03

- The U-BOT collects pallets from the R-BOT and places them in the outbound zone for manual or automated picking operations.

- STEP 04

- After picking is complete, remaining pallets are returned to storage, and the WMS updates inventory records.