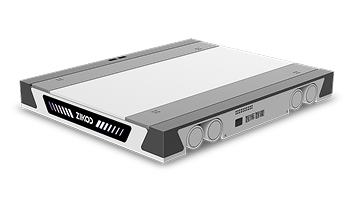

R-Bot 4-Way Pallet Shuttle

- Standard

- US Standard

- Japan Standard

- Medium-size

- Heavy-duty Pallet Type

The R-Bot 4-Way Shuttle is an intelligent storage robot designed for high-density "Pallet-to-Person" scenarios. It offers four-directional flexible movement, autonomous intelligent transportation, and seamless multi-shuttle coordination. When combined with equipment such as the H-Bot vertical bidirectional shuttle, it can adapt flexibly to various pallet storage and picking applications across multiple industries.

- - Thickness: 125 mm

- - Rated Load: 1500 kg

- - Travel Speed: 1.6 m/s

- - Direction Switching: 2.5 s

01Technological Innovations

01

Gearbox-based Power Transmission

- - Utilizes a gearbox-driven mechanical structure for exceptional durability with minimal maintenance requirements.

- - Ultra-thin design (125 mm) with a rated payload of 1.5 tons.

02

High Positioning Accuracy

Positioning accuracy of ±1 mm, below the standard distance between storage positions.

03

High-Speed Performance

- - Maximum travel speed of 2 m/s.

- - Direction switching in 2.5 seconds.

04

Extended Operating Time

- - Battery life of up to 10 hours.

- - Automatic power-saving mode for enhanced energy efficiency.

05

Multiple Model Options

- - Suitable for temperatures from -25°C to 45°C.

- - Customizable for different pallet sizes and a wide variety of operational scenarios.

06

Intelligent Operation

Features cluster scheduling, route planning, task allocation, hot-location storage optimization, and smart charging.

07

Versatile Application Scenarios

Ideal for industries including power and renewable energy, cold chain logistics, pharmaceuticals, food, 3PL, and precision manufacturing.

08

Advanced Safety Features

Multi-level obstacle avoidance and tilt detection to ensure secure pallet handling.

02Product Value

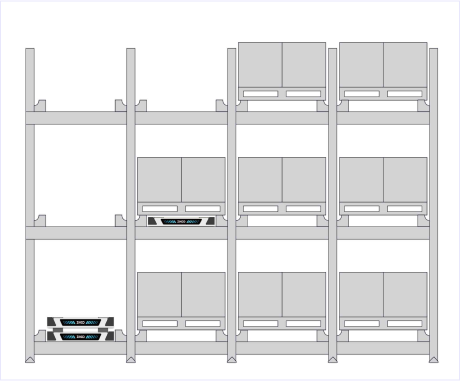

- Flexibility

- Free from fixed-path constraints, allowing access to any position within a 3D warehouse layout, ideal for complex and dynamic environments.

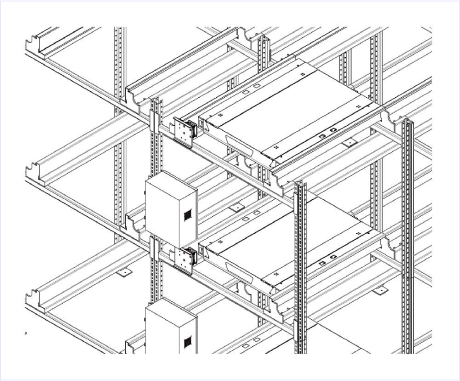

- Smart Scheduling

- Integrates with elevators, conveyors, and other devices for seamless scheduling between multiple shuttles and across various equipment layers.

- High Handling Efficiency

- Enables fully automated picking, handling, and cross-aisle/cross-level transfer to ensure smooth and efficient operations.

- High-Density Storage

- Optimizes warehouse space utilization significantly, reducing leasing costs by supporting high-density pallet storage.

R-bot 4-Way 셔틀 기술 사양

| Type | Standard | US Standard | Japan Standard | Medium-size | Heavy-duty Pallet |

|---|---|---|---|---|---|

| Model | R1200B | R1200A | R1500J | R1500B | R2000B |

| Weight (kg) | 270 | 265 | 270 | 275 | 400 |

| Rated Load (kg) | 1200 | 1200 | 1500 | 1500 | 2000 |

| Dimensions (mm) | 1000×972×125 | 1192×840×125 | 1192×900×125 | 1192×972×125 | 1250×1300×150 |

| Pallet Size (mm) | 1200×800~1000 | 1016×1219 | 1100×1100 | 12001600×10001200 | 16002000×12001400 |

| Navigation | RFID + Magnetic Guidance + Encoder | ||||

| Positioning Accuracy (mm) | ±1 | ±1 | ±1 | ±1 | ±1 |

| Speed (m/s) | 1.6/1.2 | 1.6/1.2 | 1.6/1.2 | 1.6/1.2 | 1.35/1.0 |

| Acceleration (m/s²) | 2 | 2 | 2 | 2 | 1.5 |

| Direction Switching (s) | 2.5 | 2.5 | 2.5 | 2.5 | 3.5 |

| Lifting Speed (s) | 1.5 | 1.5 | 1.5 | 1.5 | 2 |

| Battery | Lithium Iron Phosphate, 51.2V/30~40Ah | ||||

| Operating Temperature (°C) | -25~45 | ||||

| Endurance (hrs) | 6–10 | 6–10 | 6–10 | 6–10 | 5–8 |

| Charging Time (hrs) | 1.2–2 | ||||

| Certifications | CE / UL | ||||

- Cold Chain Model

-

- - Optimized lithium battery for stable operation down to -25°C.

- - RFID and laser positioning for easy maintenance.

- - Special PCBA coating for enhanced protection and a low-temperature charging port design.

- - 6–8 hours of battery life with automatic charging capability.

- - Smart power and task management for reliable cold storage operations.

- New Energy Model

-

- - Anti-static design with fully cushioned rubber wheels.

- - Constructed without copper, zinc, nickel, or lead materials, providing dustproof durability.

- - Black-coated structural components and stainless-steel racks for clean energy facilities.

Functional Modules

Emergency Rescue

- - Dedicated rescue tools for lifting and removing a faulty shuttle from racks.

- - Shuttle transfer to repair facilities using backup units.

- - Fast troubleshooting within 5–10 minutes and part replacement in 20–60 minutes for rapid recovery.

Charging Station

- - Connector designed for over 100,000 plug-in cycles, ensuring reliability.

- - Supports a temperature range of -25°C to 45°C with real-time monitoring and multiple protection features (short circuit, overload, overheating, overvoltage, overcurrent).

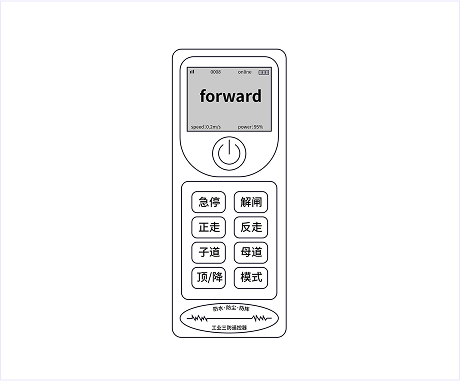

Remote Control

- - Independent wireless operation with extended communication range and strong rack signal penetration.

- - User-friendly interface with real-time status display.

- - Single remote controller can manage multiple shuttles per warehouse.