PTP Smart Warehouse Software

-

PTP (Pallet-To-Person) Smart Warehouse Software serves as the core control system of a smart warehouse, integrating storage, handling, and picking strategies while enabling seamless collaboration among multiple robots and devices. It provides a unified platform for multi-device scheduling, warehouse operation monitoring, and intelligent equipment maintenance.

01Software Architecture

Human-Computer

Interaction

APP

Mini Program

PC

Digital Large

Display

Digital Twins

- IWMS

-

Map

ManagementPolicy

configurationManagement of

multiple

warehousing areasApproval

managementContainer

ManagementAllocation

ManagementAllocation

Management

- IWCS

-

Map

ManagementCollaborative

processHandling

ManagementSorting

managementPicking

managementStorage

managementOperation

monitoring

- RMS

-

Multiple types

of schedulingMulti-robot

collaborationTraffic

controlOptimal

planning

- IoT Platforms

-

Camera

Printer

Barcode

scannerRFID

Omnidirectional

Stacker Robot

4-Way Shuttle

High-Speed

Elevator

AMR

Robotic Arm

- Supporting Systems

-

Simulation system

Design system

Implementation system

Operation and

maintenance system

- Core Algorithms

-

Task distribution

Smart inventory

managementOptimal path

Smart charging

Task management

02Key Features

- Rapid Deployment

- Flexible workflow configuration and one-click activation without additional coding

- Open and Flexible Integration

- Standard interfaces for ERP, MES, SAP, and support for various intelligent devices (e.g., wrapping machines, depalletizing robots, AGVs)

- High-Density, High-Efficiency Storage

- Supports FIFO, combined trays, and other strategies to maximize space utilization and optimize shuttle allocation

- End-to-End Data Interoperability

-

- - Manages information flow across all warehouse stages from inbound to outbound

- - Real-time pallet tracking ensures operational stability

03PTP Software

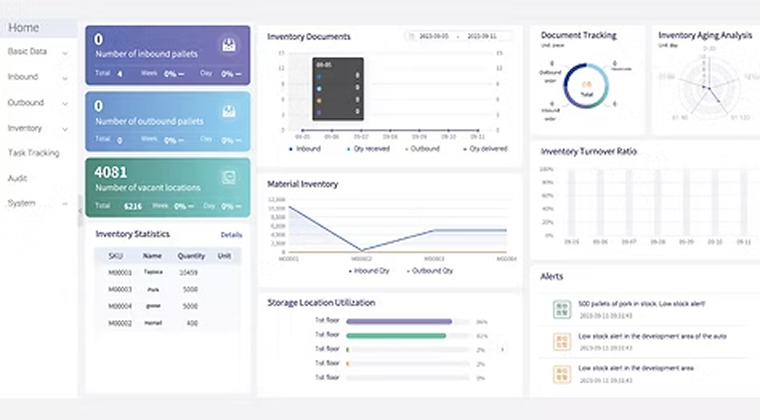

01IWMS

(Inteligent Warehouse Management System)

Automatically generates inbound/outbound workflows from purchase, production, and sales orders

Seamless collaboration with multiple container types, robots, and workstations

Built-in BI module for real-time data analysis and accurate decision-making

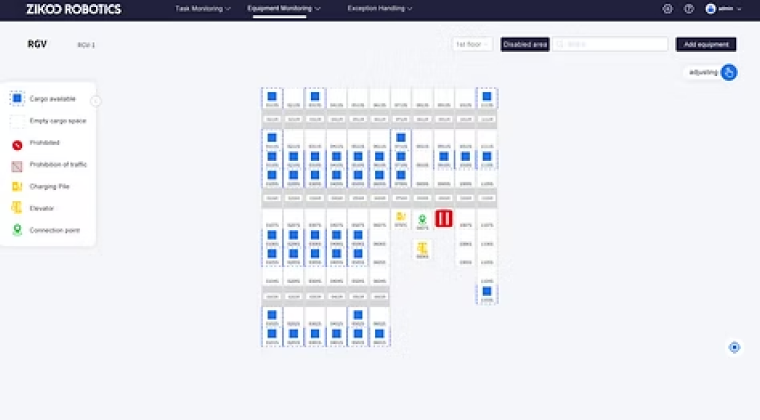

02IWCS

(Integrated Warehouse Communication System)

Automates task allocation and device collaboration

Matches available devices in real time and optimizes global scheduling for maximum efficiency and safety

03RMS

(Robot Management System)

Simultaneous scheduling for multiple robots

Collision, congestion, and deadlock prevention algorithms

Space-time-based optimal path planning and autonomous charging strategies

Multi-scenario intelligent decision-making for shuttle transfers and task handovers