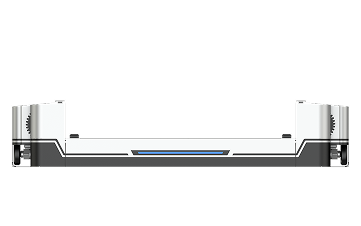

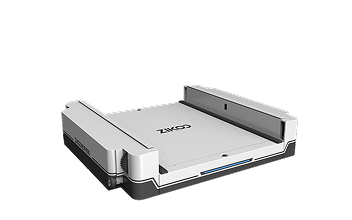

H-bot Vertical 2-Way Shuttle

- Standard Model

- US Model

- Japan Model

- Heavy-Duty Large Pallet Model

The H-bot Vertical 2-Way Shuttle is an intelligent warehouse robot designed for high-density pallet storage and picking in a "Pallet-to-Person" setup. It offers advantages such as vertical lifting, flexible layout configuration, and fast transportation. Working seamlessly with the R-bot 4-Way Shuttle, it enables true 6-Way pallet movement, replacing traditional elevators and conveyor lines to maximize space utilization and reduce operational costs.

- - Rated Load Capacity: 1,800 kg

- - Operating Temperature Range: -25°C to 45°C

- - Maximum Lifting Speed: 1 m/s

- - Positioning Accuracy: ±1 mm

01Technological Innovations

01

Refined Design

Modular platform structure ensures high reliability and easy maintenance.

02

Environmental Adaptability

Operates in extreme temperatures (-25°C to 45°C), compatible with various pallet sizes.

03

High-Speed Performance

- - Unloaded speed: 1 m/s; Loaded speed: 0.3 m/s

- - Acceleration: 2 m/s² unloaded, 0.3 m/s² loaded

04

Maximized Space Utilization

Occupies only one pallet position, increasing warehouse storage capacity.

05

Precise Positioning

Rack-and-pinion drive system guarantees ±1 mm accuracy.

06

Flexible Deployment

Can be installed both inside and outside racking structures for optimal layout design.

07

Advanced Safety Features

Multi-level protection with electric interlocks and overrun detection.

08

Fast Delivery & Installation

Standardized design enables short lead times and immediate operational readiness.

- Rack & Pinion Drive System

- The rack & pinion drive system is a proven mechanical solution that converts rotary motion into precise linear movement. By combining a gear rack and a gear pinion, it delivers:

-

- High-speed and accurate positioning for vertical shuttle operations

- Robust driving force with minimal mechanical complexity

- Durability and long service life, ideal for high-frequency warehouse environments

- This design ensures fast, reliable, and cost-efficient vertical motion control, making it a preferred choice over conventional belt or chain-driven systems in automated storage and retrieval applications.

02Product Value

- New Solution

- Combines with 4-Way Shuttle to create a complete 6-Way shuttle system.

- New Scenarios

- Ideal for high-density storage and integrated picking-storage operations.

- New Structure

- Replaces elevators with a simpler, safer, and more cost-effective system requiring no complex electrical debugging.

- New Intelligence

- Software-driven hardware control allows for remote operation and monitoring.

H-bot vs. Elevator – Key Advantages

- Shorter Lead Time

- Standardized design cuts delivery time by over 80%, reducing shipping costs significantly.

- Lower Costs

- Rack-column frame design reduces equipment cost by over 30% compared to elevators.

- Space Savings

- Occupies only one pallet position, saving over 80% of the footprint.

- Flexible Layout

- Can be installed anywhere in or outside the warehouse for optimal configuration.

H-bot 수직 2-Way 셔틀 기술 사양

| Category | Item | Unit | Standard | US Model | Japan Model | Heavy-Duty |

|---|---|---|---|---|---|---|

| Parameters | Model | - | H1800B | H1800A | H1800J | Customization |

| Weight | Kg | 345 | 325 | 335 | Customization | |

| Dimensions | mm | L1300*W1464*H288 | L1300*W1332*H288 | L1300*W1392*H288 | Customization | |

| Rated Load | Kg | 1800 | 1800 | 1800 | Customization | |

| Pallet Size | mm | 1200*800~1200 | 1016*1219 | 1100*1100 | Customization | |

| Operating Temp. | ℃ | -25~45℃ | -25~45℃ | -25~45℃ | Customization | |

| Performance | Position Accuracy | mm | ±1 | ±1 | ±1 | Customization |

| Speed (Unloaded/Loaded) | m/s | 1/0.3 | 1/0.3 | 1/0.3 | Customization | |

| Acceleration | m/s² | 2/0.3 | 2/0.3 | 2/0.3 | Customization | |

| Others | Power Consumption | KW | 16 | 16 | 16 | Customization |

| Control Mode | - | Servo | Servo | Servo | Customization | |

| Drive System | - | Rack and pinion | Rack and pinion | Rack and pinion | Customization | |

| Certifications | CE | CE | CE | Customization |