Radio Shuttle

-

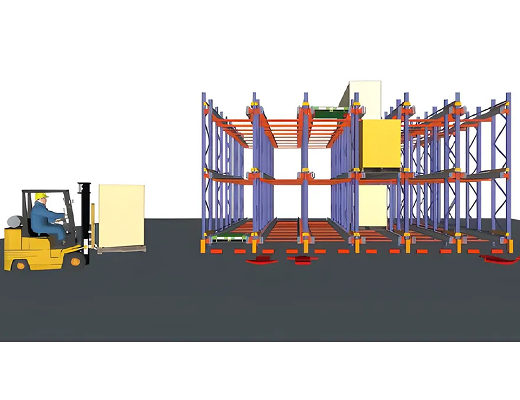

Radio Shuttle is the ideal solution for customers who do not require full automation

but need to maximize storage capacity within limited space.With only forklifts and minimal manpower, it enables high-density pallet handling with automation,

allowing you to reduce upfront investment while maximizing space utilization and labor efficiency.

In other words, it delivers the core benefits of automation without the excessive cost burden.Especially in cold storage, food & beverage logistics, and industries requiring large-volume storage,

Radio Shuttle provides a cost-effective and practical alternative that ensures both operational cost savings and a strong return on investment (ROI).

01Semi-Automated High-Density Storage Solution

- Remote-Controlled Operation

- The shuttle is operated by remote control, moving back and forth within the rack system to transport goods. At the aisle ends, forklifts pick up the pallets, simplifying loading and unloading operations.

- Automated Internal Flow

- Within the shuttle rack system, the flow of goods is automated, eliminating the need for forklift aisles and enabling maximum utilization of storage space.

- Inter-Bay Transfer

- Forklifts are used for movement between different rack bays.

- Application Fit

- With a structure similar to drive-in racking systems, the radio shuttle is ideal for high-density storage in cold storage, the food & beverage industry, and other sectors with low SKU variety.

02Recommended Applications

Low SKU

environments

Bulk volume

storage

High-density

warehousing

- System Advantages

- Automated pallet loading/unloading and organization based on an automation system

- Efficient loading/unloading system that ensures high accuracy with minimal investment

- Applicable to any warehouse regardless of existing space size

- Maximized storage capacity utilization: improves space usage from 40% up to 80%

- Reduced labor costs through enhanced work efficiency (higher accuracy, faster speed, improved allocation efficiency)

- Compared to drive-in systems, automated order picking efficiency improves by 2–3 times

- Compatible with pallets of various sizes

- Since forklifts do not enter the rack units, rack damage is reduced

- Ideal for cold storage applications (down to -25°C)

- Supports WCS and WMS software

- Enables remote monitoring and control